2) Single Acting

Cylinder:

These cylinders

have power strokes in one direction only.Return Types

available are:a) Sping return:

1) Air to forward piston / spring to return

piston.2) Air to retract

piston / spring to forward piston. b) Return by external

load: Air to forward or return piston and original

position achieved by external load. These cylinders

have power strokes in one direction only.Return Types

available are:a) Sping return:

1) Air to forward piston / spring to return

piston.2) Air to retract

piston / spring to forward piston. b) Return by external

load: Air to forward or return piston and original

position achieved by external load.

|

| |

Power Stroke in

single acting cylinder is achieved only in one direction

of piston movement. Return stroke is achieved by any of

the methods mentioned above. Seed and pull force of

return stroke is dependent on the stiffness of the

spring used and the mode of flow control available.

These cylinders are used in applications where the

piston is to be in the original / neutral position in

the case of power failures

etc. |

|

| |

3) Double Ended

Cylinder :

The piston rod in

this case is extended from both the sides of the piston

and the power stroke is available in both the

directions. An example could be the clamping of the

workpiece to be moved onto the cylinder body rather than

the piston shaft. The piston rod in

this case is extended from both the sides of the piston

and the power stroke is available in both the

directions. An example could be the clamping of the

workpiece to be moved onto the cylinder body rather than

the piston shaft.

|

| |

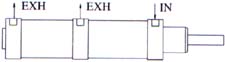

4) Tandem

Cylinder:

These are two double

acting cylinders coupled together with a common piston rod and

find applications where there is space constraint to use a

larger bore for achieving the requisite force. These are two double

acting cylinders coupled together with a common piston rod and

find applications where there is space constraint to use a

larger bore for achieving the requisite force.  The force

achieved by a tandem cylinder is 1.8 times that of a double

acting cylinder of the same bore eg.force obtained by 200 mm

bore cylinder at 5 bar is around 1.6 tonnes. This same force

can be obtained using a tandem cylinder of bore size 150

mm. The force

achieved by a tandem cylinder is 1.8 times that of a double

acting cylinder of the same bore eg.force obtained by 200 mm

bore cylinder at 5 bar is around 1.6 tonnes. This same force

can be obtained using a tandem cylinder of bore size 150

mm.

|

| |

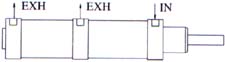

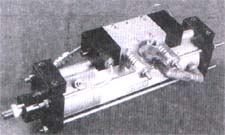

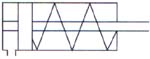

5) Continuous

Reciprocating Type: 5) Continuous

Reciprocating Type:

Also known

depicted as linear air motor, these units are self

reciprocating air cylinders which require no external

valves or limit switches. Just one air input is required

to operate the cylinders. Speed of forward and return

stroke can be adjusted by the flow control valves

mounted on the cylinders. |

| |

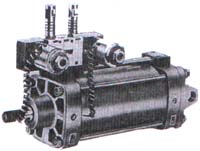

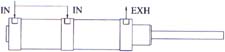

6) Valve Mounted

Cylinder: 6) Valve Mounted

Cylinder:

This incorporates

a double acting cylinder with valve mounted directly on

it. This avoids excessive piping as just an inlet

pressure is required to be given to the inlet of the

valve. Outlets ports of the valve are pre-connected to

the ports of the cylinders. This cylinder is not

continuously reciprocating type. On / Off switches are

required to enable the forward and return

stroke. |

| |

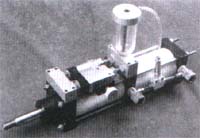

7) Feed Control

Cylinder: 7) Feed Control

Cylinder:

In general

applications, the speed of a cylinder can be controlled

using flow control valves. However, in applications

which require very precise speed control without jerks,

the feed control cylinder is recommended.

Hydro-pneumatic system provided in the cylinder enables

achievement of velocities as low as 50 mm per

minute. |

| |

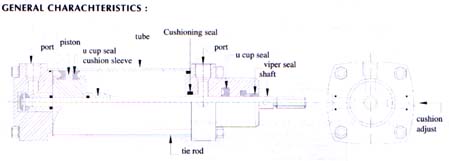

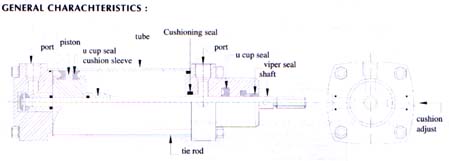

| Working Characteristics of

Pneumatic Cylinder |

|

| Material Specification: |

| Cylinder

tube |

Seamless hard

drawn low carbon steel tube, honed and hard chrome

plated internally to 60 RC increases seal life. Bores:

40 to 300 mm.Seamless Hard

drawn brass tube internally polished : Bores : 19 to 65

mm |

| Piston

rod |

EN8 ground, micro

finished and hard chrome plated for lasting seal life

and corrosion resistance. |

| Seals |

Piston and cushion

seals made from a wear resistant nitrile rubber

compound. The double lip seal design automatically self

compensates against wear. |

| Piston |

Cast

iron |

| End

covers |

Cast iron oxidised

to prevent

corrosion |

|

| |

| Media |

Air, Oil and inert

gas |

| Temperature range |

-20 to 85 degrees

cen. |

| Pressure |

150 p.s.i. / 10 bar |

| Cushioning |

available in bore sizes 32 and above

only. |

|

| Note: The internal finish of brass tube has

been known to improve in continuous operation with the passage

of time thereby reducing friction. |

| |

direction control

valves

Direction Control

Valves are used for operating air / power cylinders. It is a

prerequisite to identify the correct type of valve suitable to

the relevant application. A detailed description of the types

of valves and their application is illustrated

below:

1) SPOOL TYPE: SERIES

11

2) DIRECT ACTING

TYPE: SERIES 12

3) POPPET TYPE:

SERIES 16

SPOOL TYPE VALVES

(SERIES 11)

The movement by the

piston in the cylinder is achieved by the alternate flow of

compressed air guided by the position of the spool in the

valve. The position of the spool is governed by external means

of actuation which could be manual or

electrical.

Selection of spool

valve is based on the following criteria:

1) FORWARD OPERATING

MECHANISM OF SPOOL

2) RETURN OPERATING

MECHANISM OF SPOOL

3) NUMBER OF

PORTS

4) NUMBER OF

POSITIONS

5) PORT

SIZE |

| |

| 1) FORWARD OPERATING MECHANISM OF

SPOOL |

2) RETURN OPERATING MECHANISM OF

SPOOL |

ACTUATION |

TYPES |

ACTUATION |

TYPES |

MANUAL |

Hand Lever / Foot

Pedal / Palm |

MANUAL |

Hand Lever / Foot

Pedal / Palm |

SOLENOID

COIL |

6 to 220 V D.C. 6

to 400 V A.C. |

SOLENOID

COIL |

6 to 220 V D.C. 6

to 400 V A.C. |

PILOT

AIR |

External |

PILOT

AIR |

External |

MECHANICAL |

Roller / Roller

Lever |

MECHANICAL |

Roller / Roller

Lever |

|

| |

| 3) NUMBER OF PORTS |

No. of

Ports |

Types |

PP: Pressure

port

(pressure line in) |

4) NUMBER OF

POSITIONS: (a) Two position, (b) Three

position

5) PORT

SIZE: Indicates the size of the ports of

the valve to which pipe fittings are made. Where it is

required to have higher flow rate, it is taken as a

rough assumption that the larger the port size, higher

is the flow rate leading to increase in linear speed of

cylinder. "LUTHRA" make offers port valve sizes ranging

from 1/8" B.S.P. to 3/4" B.S.P. |

2

Ports |

1 PP / 1

OP |

OP: Outlet

port |

3

Ports |

1 PP / 1 CP / 1

EP |

EP: Exhaust

port |

5

Ports |

1 PP / 2 CP / 2

EP |

CP: Compressor

port |

|

| |

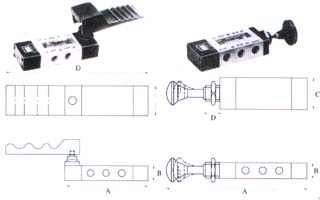

| SERIES

11: SPOOL OPERATED

VALVES |

| GENERAL VALVE

CHARACTERISTICS |

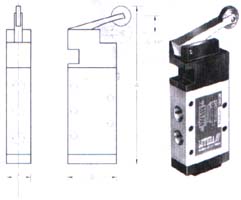

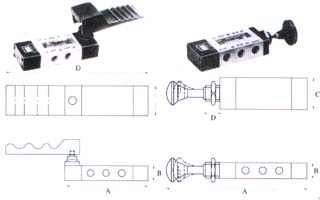

HANDLEVER

OPERATED:

|

| BODY |

ALUMINIUM HARD

ANODIZED |

| SPOOL |

ENB HARD CHROME

PLATED |

| SEALS |

NITRILE /

VITON |

| TEMPERATURE |

-10 TO 80 / -10 TO

250 DEG. CEN. |

| PORT

SIZE |

1/4", 3/8", 1/2" B.

S. P. |

| MEDIA |

AIR / FLUID

* |

| PRESSURE

RANGE |

AS PER TYPE OF

VALVE |

| *: fluid media

application valid for all spool valves except for 3 port

& 5 port solenoid operated valves |

|

| |

| FOOT OPERATED VALVE |

|

PALM BUTTON OPERATED |

|

| |

TYPE |

SIZE |

A |

B |

C |

D |

1) 5/2 Spring

return |

1/4" |

134 |

25 |

50 |

214 |

3/8" |

216 |

38 |

68 |

320 |

1/2" |

216 |

38 |

68 |

320 |

4) 3/2 Spring

return |

1/4" |

110 |

25 |

50 |

190 |

3/8" |

176 |

38 |

68 |

280 |

1/2" |

176 |

38 |

68 |

280 |

|

| |

| Pressure

range |

0 to 10

bar |

TYPE |

SIZE |

A |

B |

C |

D |

1) 5/2 Spring

return |

1/4" |

175 |

25 |

50 |

15 |

3/8" |

255 |

38 |

68 |

15 |

1/2" |

255 |

38 |

68 |

15 |

2) 5/2 Detent

type |

1/4" |

170 |

25 |

50 |

15 |

3/8" |

250 |

38 |

68 |

15 |

1/2" |

250 |

38 |

68 |

15 |

4) 3/2 Spring

return |

1/4" |

150 |

25 |

50 |

15 |

3/8" |

215 |

38 |

68 |

15 |

1/2" |

215 |

38 |

68 |

15 |

5) 3/2

detent |

1/4" |

155 |

25 |

50 |

15 |

3/8" |

220 |

38 |

68 |

15 |

1/2" |

220 |

38 |

68 |

15 |

|

| |

| Pressure

range |

2 to 10

bar |

TYPE |

SIZE |

A |

B |

C |

D |

1) 5/2 Spring

return |

1/4" |

134 |

25 |

50 |

120 |

3/8" |

216 |

38 |

68 |

150 |

1/2" |

216 |

38 |

68 |

150 |

2) 5/2 Detent

type |

1/4" |

138 |

25 |

50 |

120 |

3/8" |

209 |

38 |

68 |

150 |

1/2" |

209 |

38 |

68 |

150 |

3) 5/3

Detent |

1/4" |

138 |

25 |

50 |

120 |

3/8" |

209 |

38 |

68 |

150 |

1/2" |

209 |

38 |

68 |

150 |

4) 3/2 Spring

return |

1/4" |

109 |

25 |

50 |

120 |

3/8" |

175 |

38 |

68 |

150 |

1/2" |

175 |

38 |

68 |

150 |

5) 3/2

Detent |

1/4" |

1131 |

25 |

50 |

120 |

3/8" |

179 |

38 |

68 |

150 |

1/2" |

179 |

38 |

68 |

150 |

6) 3/3

detent |

1/4" |

113 |

25 |

50 |

120 |

3/8" |

179 |

38 |

68 |

150 |

1/2" |

179 |

38 |

68 |

150 |

|

| |

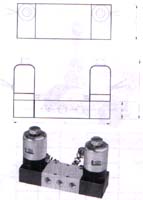

| SERIES 11: SPOOL OPERATED

VALVES |

| DOUBLE PILOT |

SINGLE PILOT |

|

PRESSURE RANGE |

2 to 10

bar |

|

PRESSURE RANGE |

2 to 10

bar |

| TYPE |

SIZE |

A |

B |

C |

TYPE |

SIZE |

A |

B |

C |

| 1) 5/2 Detent

type |

1/4" |

138 |

30 |

50 |

1) 5/2 Spring

return

|

1/4" |

138 |

25 |

50 |

3/8" |

216 |

38 |

68 |

3/8" |

216 |

38 |

68 |

1/2" |

216 |

38 |

68 |

1/2" |

216 |

38 |

68 |

| 2) 3/2

detent |

1/4" |

115 |

30 |

50 |

4) 3/2 Spring

return

|

1/4" |

113 |

25 |

50 |

3/8" |

176 |

38 |

68 |

3/8" |

176 |

38 |

68 |

1/2" |

176 |

38 |

68 |

1/2" |

176 |

38 |

68 |

|

| |

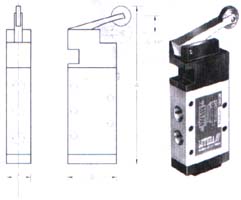

| ROLLER OPERATED |

ROLLER REVER OPERATED |

|

PRESSURE RANGE |

0 to 10

bar |

|

PRESSURE RANGE |

0 to 10

bar |

| TYPE |

SIZE |

A |

B |

C |

D |

TYPE |

SIZE |

A |

B |

C |

| 1) 5/2 Spring

return |

1/4" |

140 |

25 |

50 |

5 |

1) 5/2 Spring

return |

1/4" |

150 |

50 |

25 |

3/8" |

222 |

38 |

68 |

5 |

1/2" |

222 |

38 |

68 |

5 |

| 4) 3/2 Spring

return |

1/4" |

125 |

25 |

50 |

5 |

4) 3/2 Spring

return |

1/4" |

125 |

50 |

25 |

3/8" |

180 |

38 |

68 |

5 |

1/2" |

180 |

38 |

68 |

5 |

|

| |

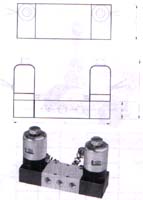

| SERIES

11: SPOOL OPERATED

VALVES |

COIL

CHARACTERISTICS |

COIL |

EPOXY MOULDED (WEATHER

PROOF) |

COIL HOUSING |

HARD CHROME

PLATED |

VOLTAGE |

6 TO 440 V a.c. / 6 TO 220 V

d.c. |

POWER CONSUMPTION |

11 WATTS |

INSULATION |

CLASS

'H' |

|

| |

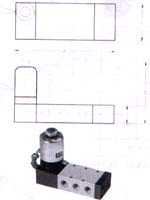

|

SINGLE SOLENOID OPERATED |

|

DOUBLE SOLENOID OPERATED |

| TYPE |

SIZE |

A |

B |

C |

D |

TYPE |

SIZE |

A |

B |

C |

D |

| 1) 5/2 Spring

return |

1/4" |

145 |

30 |

50 |

105 |

1) 5/2 Retaining

type |

1/4" |

164 |

30 |

50 |

105 |

3/8" |

216 |

38 |

68 |

105 |

3/8" |

216 |

38 |

68 |

113 |

1/2" |

216 |

38 |

68 |

105 |

1/2" |

216 |

38 |

68 |

113 |

3/4" |

250 |

42 |

85 |

117 |

3/4" |

246 |

42 |

85 |

117 |

| 2) 3/2 Spring

return |

1/4" |

125 |

30 |

50 |

105 |

2) 5/3 Spring

centered |

1/4" |

194 |

30 |

50 |

105 |

| 3/8" |

260 |

38 |

68 |

113 |

3/8" |

216 |

38 |

68 |

105 |

1/2" |

260 |

38 |

68 |

113 |

4) 3/2 Retaining

type |

1/4" |

140 |

30 |

50 |

105 |

3/8" |

175 |

38 |

68 |

113 |

1/2" |

175 |

38 |

68 |

113 |

1/2" |

216 |

38 |

68 |

105 |

5) 3/3 Spring

centered |

1/4" |

170 |

30 |

50 |

105 |

3/8" |

220 |

38 |

68 |

113 |

1/2" |

220 |

38 |

68 |

113 |

|

| |

| Pressure

range |

2 to 10

bar |

|

Pressure range |

1/4", 3/8", 1/2" |

2 to 10 bar |

1/4", 3/8", 1/2" |

1.5 to 10 bar |

3/4" B.S.P. |

4 to 10 bar |

|

2.5 to 10

bar |

|

| Top |

Alternate air supply to the cylinder is achieved by a 5

port / 4 port valve as illustrated in the section for

valves.

Alternate air supply to the cylinder is achieved by a 5

port / 4 port valve as illustrated in the section for

valves.  These are two double

acting cylinders coupled together with a common piston rod and

find applications where there is space constraint to use a

larger bore for achieving the requisite force.

These are two double

acting cylinders coupled together with a common piston rod and

find applications where there is space constraint to use a

larger bore for achieving the requisite force.  The force

achieved by a tandem cylinder is 1.8 times that of a double

acting cylinder of the same bore eg.force obtained by 200 mm

bore cylinder at 5 bar is around 1.6 tonnes. This same force

can be obtained using a tandem cylinder of bore size 150

mm.

The force

achieved by a tandem cylinder is 1.8 times that of a double

acting cylinder of the same bore eg.force obtained by 200 mm

bore cylinder at 5 bar is around 1.6 tonnes. This same force

can be obtained using a tandem cylinder of bore size 150

mm. 5) Continuous

Reciprocating Type:

5) Continuous

Reciprocating Type: 6) Valve Mounted

Cylinder:

6) Valve Mounted

Cylinder: 7) Feed Control

Cylinder:

7) Feed Control

Cylinder: