| |

| Plywood

>> |

| BWR

/ MR Plywood |

|

Made from high quality veneers of uniform thickness

& bonded with phenol / urea formaldehyde resin

with addition of chemicals as per IS : 848. Suitable

for furniture, wall paneling, cupboards, partitions,

shelves, Ceilings etc.

Manufactured with veneers of uniform thickness of

high density farm timber dried on mechanical drier,

stress relieves, bonded with the best quality phenol

/ urea formaldehyde as per IS:848 and than treated

with chemical in a dipping tank as per IS:401 : 1982

make it termite and wood.boring insects resistant.

Suitable for home, offices, industry, Kitchen, paneling,

bus and truck bodies, railway coaches etc.

|

| |

| Property |

Unit |

Requirement of IS 303 (BWR/MR) |

Test Result |

| Shear Strength

in Wet State |

| Average

Min |

N/mm2 |

1350/1000 |

1600/1350 |

| Indivisual

Min |

N/mm2 |

1100/800 |

1300/100 |

| Shear

Strength in Wet State |

| Average Min |

N/mm2 |

1000/800 |

1300/1000 |

| Indivisual

Min |

N/mm2 |

800/650 |

100/900 |

| Shear

Strength in Mycological Test |

| Average Min |

N/mm2 |

1000/800 |

1300/1000 |

| Indivisual

Min |

N/mm2 |

800/650 |

1100/900 |

| Moisture Content |

% |

5-15 |

6-10 |

|

| |

| BWR / MR Block

Plywood |

|

Manufactured from durable species of timber duly

kiln seasoned, sand witched between drier dried quality

veneers and bonded as per IS : 848 with imported Gurjan

/ Keruing face. The final Product is treated chemically

by dipping process to make it resistant to termite,

borer and other wood destroying organism. Suitable

for paneling, partitions, furniture, cupboards, kitchen

shelves, cabinets, racks etc.

Made from Kiln seasoned, durable species of timber

& bonded with quality Phenol formaldehyde resin

as per ISI specification. They are structurally strong,

custom finished as per consumers requirements. Suitable

for Houses, Offices, Industries, furniture etc.

|

| |

| Property |

Requirement of IS 1659 (BWR/MR) |

Test Result |

| Moisture Content |

5-15 |

8-10% |

| Changes caused

by humidity |

Less than 1mm |

Less than 0.6mm |

| Adhesive of ply |

Good |

Excellent |

| Water resistance |

8 Hours at

60oC / 24 Hrs at 100oC |

More than 12

Hrs. at 60oC / More than 72 Hrs. at 100oC |

| Mycological Test |

One cycle of

21 days |

Can undergo

3 cycles of 21 days each without any edge superation. |

| MOR |

40N / mm2

/ 50N / mm2 |

More than 45N

/ mm2 / More than 55N / mm2 |

| MOE |

4000 / 5500

(N/mm2) |

4500 / 5500

(N/mm2) |

|

| |

| Film

Faced Shuttering Plywood |

|

- Smooth silky mirror like finish.

|

- Phenol coating helps maintain shape and prevents swelling.

|

- Can withstand and maintain shape when concrete is poured

into it.

|

- Scratch and abrasion resistant.

|

- Available in the attractive Brick-Red colour only.

|

| |

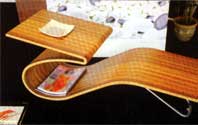

| Flexi

Plywood |

|

Our Flexible Plywood is one more special product from our

house. Our Flexible Ply is a suitable crofted product to

render flexibility for curves, rounds and corners, igniting

any designer's imagination. Normally, for pillars and corners,

people use 4mm normal plywood that do not give the perfect

round look and it is not long lasting because of the wrong

application.

The Corner ply fits exactly into the requirement which

is available in thickness 4mm to 18mm. The flexibility of

Corner ply is like a rubber.

|

|

| Powered

By : www.calcuttayellowpages.com |

|

|