|

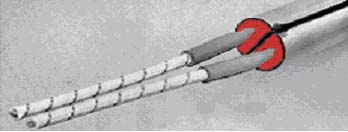

Split Sheath High Watt

Density Cartridge Heaters |

Heatco make High Watt Density Split Sheathed Cartridge Heaters uses less power, runs more efficiently and survives more that that of cylindrical type conventional Cartridge Heaters. Due to its elongation capability it clutches the mould when energized leaving no air gap and contracts when it cools down parting the following advantage.

- Maximizes Heat Transfer

- Easy Maintenance

- Reduces the Cost of operation.

The construction of Heatco make High Watt Density Split Sheathed Cartridge Heaters eliminates ceramic cores typically found in conventional cartridge heaters. Heatco with its continuous in house research and possessing highly-specialized manufacturing techniques compacts fused magnesia around the heater coil in such a way that increases dielectric strength and heat transfer away from the coil which results in significantly longer heater life. The heaters contract when de-energized, eliminating bore seizure and the need for expensive drill-outs. The construction of Heatco make High Watt Density Split Sheathed Cartridge Heaters eliminates ceramic cores typically found in conventional cartridge heaters. Heatco with its continuous in house research and possessing highly-specialized manufacturing techniques compacts fused magnesia around the heater coil in such a way that increases dielectric strength and heat transfer away from the coil which results in significantly longer heater life. The heaters contract when de-energized, eliminating bore seizure and the need for expensive drill-outs.

Advantages High Density Split type Cartridge Heater:

- Easily Replaceable

- Longevity

- Fast Heat Transfer

- Higher Watt Densities

- Higher Operating Temperature

Standard Dimensions of Heatco make High Watt Density Cartridge Heater

|

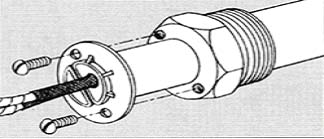

| Low Watt Density Cartridge Heaters |

Though we have a standard range of Heatco make High Density Split Sheathed Heater we usually manufacture tailor made cartridge heaters as per the requirement of our clients to match their heating requirements in lieu to the size.

Applications :

- Dies & Moulds

- Package Sealing

- Liquid Heating.

- Food Services

|