|

|

| |

|

|

Scaffolding is simply described as a temporary assembly normally attached to a construction that allows us to gain better access to the exterior or interior form of that construction in order to repair, improve or develop it in some way. Without scaffolding, workers would be unable to obtain a safe working platform for carrying out engineering or development work on a structure.

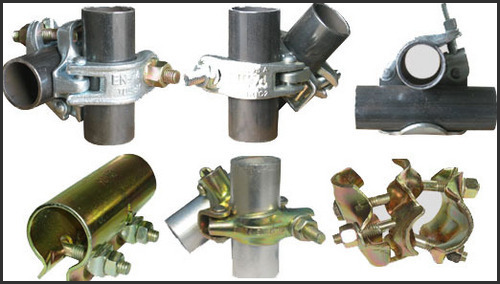

Scaffolding is made up of many different scaffolding components, each used to enable a strong, safe and reliable connection between scaffold tubes to help provide this improved access. The main basic components are scaffold tubes, couplers and scaffold boards. |

| |

| |

Scaffold Tubes |

|

Scaffold tubes or pipes, are manufactured out of either steel or aluminium. Aluminium pipes, while lighter, are not as strong as steel scaffold tubes, and are therefore not recommended for any long-term or heavy-duty usage. Steel scaffold tubes are highly recommended for anything more than very light, low-level, and non-weight bearing usage. |

|

| |

| |

Scaffold Couplers |

|

Other scaffolding components, such as couplers, are often made from either drop-forged steel, or pressed steel, both of which materials produce highly durable components which, when installed by competent individuals, are easily capable of withstanding very high workload. |

|

| |

| |

Ledgers, Standards and Transoms |

|

In terms of the basic structure of scaffolding, the three main components are the standards (the vertical scaffold poles that bear the weight of the scaffolding), the ledgers (the horizontal poles that attach to each standard), and transoms (main transoms are attached at 90 degrees to ledgers adjacent to the standards, intermediate transoms are attached at set distances apart 90 degrees to the angle of the ledgers and are used to provide support for scaffold boards). |

|

|

|

|