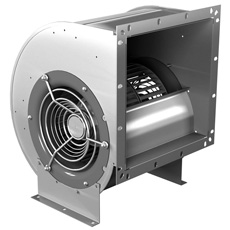

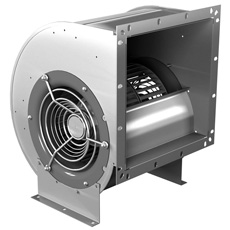

Pasko Centrifugal fans are widely used in the Heating, Ventilation & Air-conditioning fields. Our products are designed to meet customers' individual specification. Whatever the requirement, be it high efficiency, low noise, clean air, handling light dust or large solid particles; a suitable centrifugal fan can be found from our range.

• Applications

- General HVAC & R

Material Handling

Material Handling- Chemical Process

- Induced Draft

- Dust Collection

- Dust Control

- Pressure Blower

- Painting plants

- Rotogravure

- Food industry

- Incinerators

- Industrial processing, etc.

• Casing

• Casing

The fan casings are fabricated out of continuously welded heavy gauge steel sheets with smooth exterior & interior to equalize the flow of air over the entire outlet area. Stationary vanes are used to increase efficiency with reduced turbulence & noise.

• Impelle

The impellers with deep, wide blades are very rigid and efficient. All impellers are precisely balanced both statically & dynamically to offer balanced rotor whirl. Centrifugal fan impeller designed by us include: backward curved, backward aerofoil, backward inclined, forward curved, radial blade etc. Standard impellers are made of mild steel. Stainless steel / FRP coated impellers can also be provided.

• Shaft

• Shaft

The shafts are liberally sized to run well below critical speed and made of high quality hot rolled steel or alloy steel depending on application.

• Bearing

Correct bearing design ensures long life and trouble free operation. For standard fans heavy duty double row self aligning ball bearings are used. Roller or Sleeve bearings can also be provided if needed.

• Fan Drive Systems :

• Fan Drive Systems :

The fan assembly could be mounted on a wide range of driving systems to meet the desired range of performances and applications. These includes direct drive, belt drive, gear drive etc.

• Fan Performance

The way Pasko fan impellers (blades or rotors) are designed, the amount of air they can move decreases as the pressure they are working against increases. The airflow vs. pressure information for a particular fan is called the fan performance data. The performance of a fan depends on the size, shape & speed of the impeller. The fan performance data is essential for selecting fans as per the desired airflow and system pressure.

• Fan Types

• Fan Types

- Low Pressure

- Medium Pressure

- High Pressure

- Belt Drive

- Single/Double Inlet

- Direct Coupled

• SPECIAL FEATURES - Premium Efficiency Airfoil blade.

- High Efficiency Single thickness blade.

- Single and Double width construction.

- High temperature construction.

-

Corrosion resistant.

Corrosion resistant.

- Non-Sparking.

- Non-Overloading.

- Damper controlled.

- AC Variable speed drive.

- Belt, Direct drive.

- Direct coupled.

- Drive guards.

- Lower noise level.

- Dynamically balanced impellers.

- Compact design for restricted space.

- Corrosion free parts.

- Excellent finish with matching colors.

- Minimum power consumption

- Trouble free operation.

- Prompt after sales service.

- Affordable prices.

• Product Description :

01) A large selection of outlet positions, casing geometries, casing thicknesses and materials is available for the various fan types. The following is a description of our standard product range.

02) Impeller diameter 300 up to 1600

02) Impeller diameter 300 up to 1600

03) Casing thickness Up to 12

04) Casing types Low/Medium/High pressure (up to 800 mm WC)

05) Impeller types As required.

06) Motor frame size 63 up to 280

07) Drive type Direct, coupling or belt drive

08) Material Steel, aluminum, special alloys

09) Surface treatment Primer, finish, Hot dip galvanized, special.

10) Outlet position As per requirement

11) Special design Flame-proof, High temperature (up to 250 0C, gas-tight, de-contaminable, corrosion resistant, shock proof, as per requirement.

• Standard Accessories :

- Silencer

- Sound Enclosures

- Case Insulation

- Vibration Attenuator

- Counter Flange

- Flexible Connection

- Protection Grill

- Outlet/Inlet damper

• Standard arrangements :

The following two arrangements are commonly used.

- Arrangement 1 : Impeller wheel is overhung, two bearings on a base.

-

Arrangement 3 : The impeller wheel is supported by fan housing with one bearing on each side.

Arrangement 3 : The impeller wheel is supported by fan housing with one bearing on each side.

- Arrangements 2, 4 - 9 can also be made if needed.

- Inlet cone

- Protection grill

- Wall cowl

- Feet for horizontal/vertical position

- Vibration attenuator

- Flexible connection

- Counter flange

- Silencer

Material Handling

Material Handling • Casing

• Casing • Shaft

• Shaft  • Fan Drive Systems :

• Fan Drive Systems : • Fan Types

• Fan Types Corrosion resistant.

Corrosion resistant. 02) Impeller diameter 300 up to 1600

02) Impeller diameter 300 up to 1600 Arrangement 3 : The impeller wheel is supported by fan housing with one bearing on each side.

Arrangement 3 : The impeller wheel is supported by fan housing with one bearing on each side.