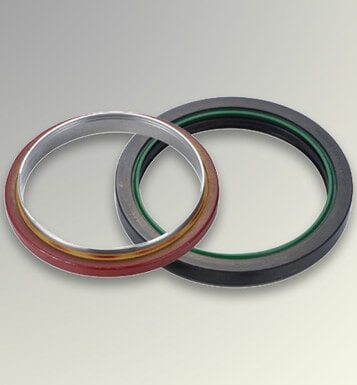

These are fitted between machine parts in relative rotations; their name indicating that these are seals designed in form of ring that separate oil or grease present inside from the outer particles like dirt, water and dust. Mainly comprising of elastomeric diaphragm, shaped in the formation of a "lip" is reinforced with co-vulcanized metal insert. A "Greater Spring" energizes the sealing lip.

The sealing lip design corresponds to the current state of art and is based on many years of experience in a wide range of application fields. The sealing edge can either be ready molded or trimmed by mechanical cutting. The total radial force of the sealing lip is given by elastomeric pre-tension together with tensile spring force. The former depends on the deformation and elasticity of the rubber material, geometry of the sealing lip and interference between shaft and seal.